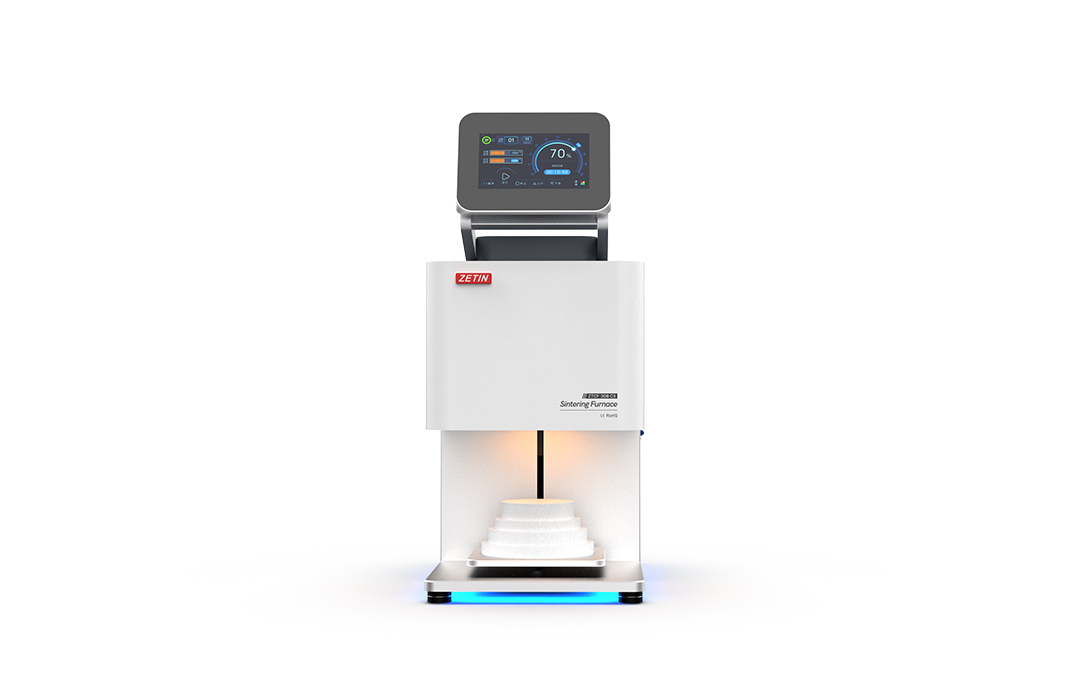

Made for dentists the porcelain oven is within easy reach

The dental porcelain oven has been greatly upgraded, and you can feel the beauty of dental porcelain up close

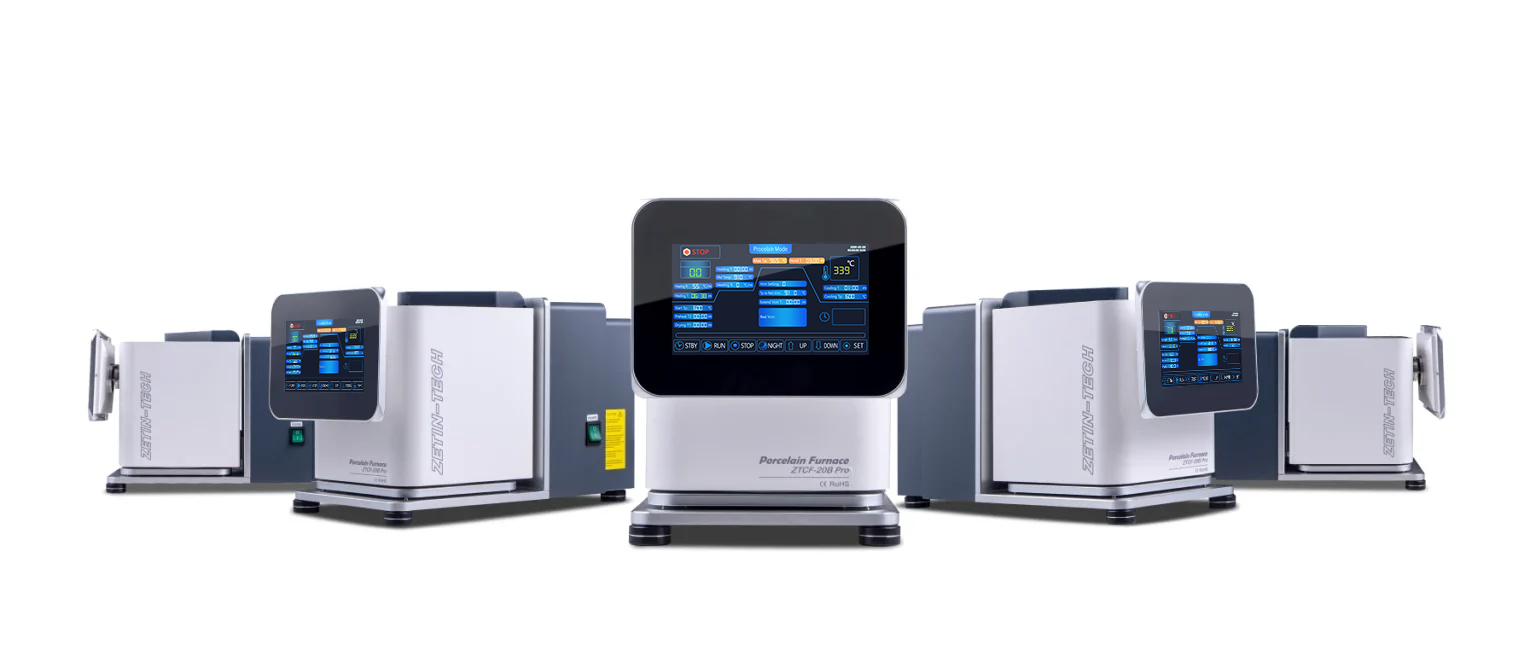

High speed, high quality, and high quantity

make sintering more than just fast

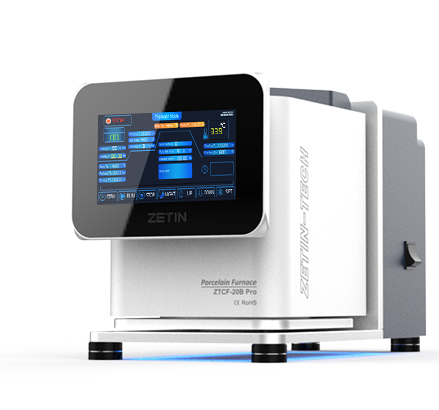

Chairside Porcelain Furnace

ZTCF-20B Pro

- Reduce the size of the device

- Improve sintering accuracy

- Improve process fit

- Streamline operations

Solutions to four core problems: 1. The equipment application environment is narrow. This product is dedicated to dentists, optimizes the appearance design of the product, and creates the original lifting furnace, which effectively reduces the volume of the equipment, reduces the weight of the equipment, and optimizes the aesthetics, and has a beautiful appearance of different colors, which adapts to the multiple choices of different dental clinics. 2. The sintering accuracy is insufficient. Traditional equipment has large temperature fluctuations (more than ±15°C), resulting in bubbles in the porcelain layer and poor edge tightness, this product ensures zero defects in the restoration through high-precision PID control (±1°C). 3. Poor process adaptability. This product is compatible with all porcelain materials such as zirconia and glass ceramics, and presets 3 kinds of porcelain powder sintering programs to avoid manual debugging errors. 4. The operation is complex and time-consuming. This product adopts a one-button start intelligent program, which increases the sintering efficiency by 40% and lowers the learning threshold for technicians.

Ensure sintering quality

Lifting furnace

Smooth operation and uniform heating

Imported heating wire

Uniform heating, ensuring sintering quality, long service life, and reducing maintenance costs

Imported sensors

Accurate measurement of vacuum level, effective removal of gases, reduction of oxidation reaction, ensuring uniform melting of porcelain powder, and improving the tightness of restorations

± 1 ℃ temperature error

PID intelligent temperature control system improves sintering quality and reduces consumables consumption

New insulation materials

Good thermal insulation effect, energy saving and high efficiency

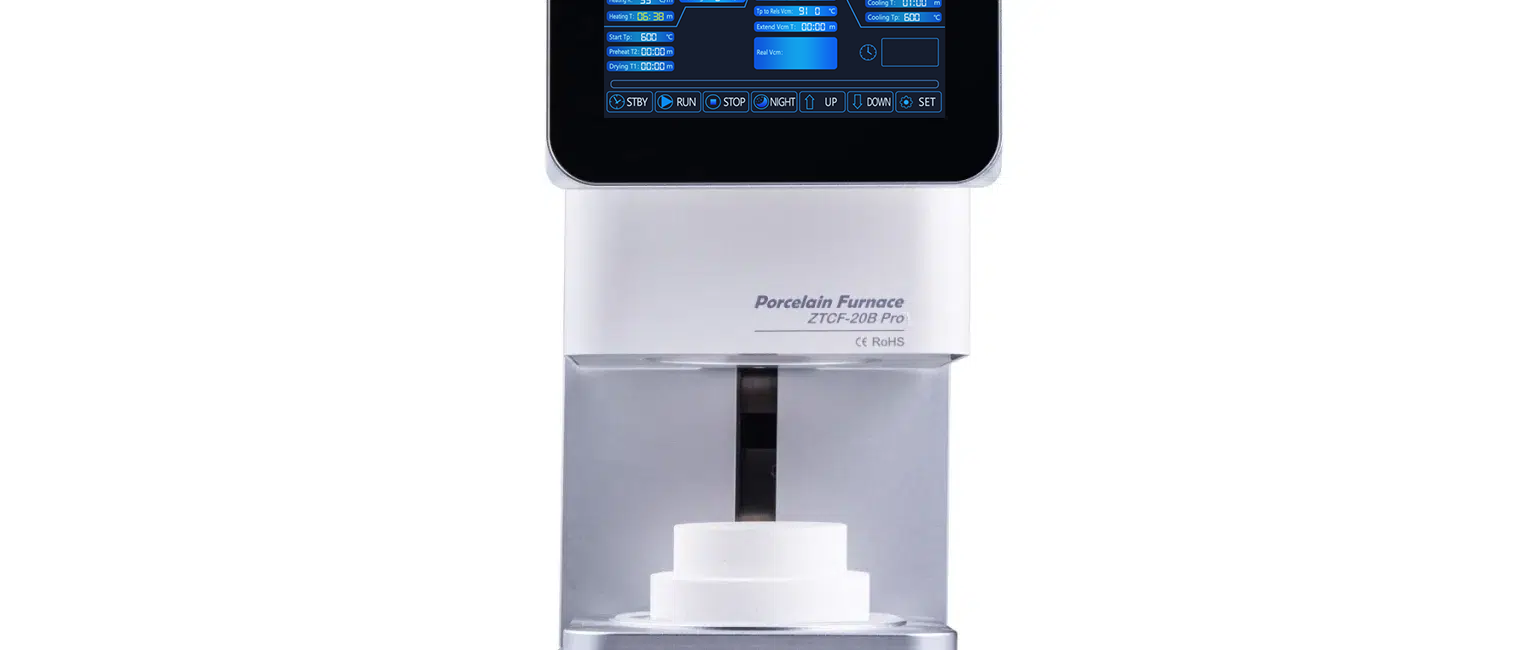

Convenient operating system

7-inch high-definition color touch screen

Data visualization interface design, scientifically reasonable button layout, simple and easy operation, reducing job training and improving work efficiency

3 major program selection

Built-in Yihujia, Vita, Zewu porcelain powder program, users can choose independently according to material needs, with wide adaptability to ensure the smooth progress of work

Professional supporting design

Oil-free vacuum pump

Long service life, high vacuum value, maintenance-free, low noise

Vacuum line filtration

Protect the relevant core components from damage, increase the service life of the equipment, and reduce maintenance costs

Technical parameters

Max.Temperature: 1300℃

Max.Vacuum: -98Kpa

Heating Rate: ≤140℃/min

Total Program No.: 100 programs (Can extend to 500 programs)

Power: 1600W

Voltage: 220V 50/60HZ

Chamber Size: ∅100mm*70mm

Size: 460*220*300 mm(L*W*H)

Net Weight: 18KG

Large Touch Screen

Large touch screen, parameterized design interface, and panoramic display of all parameters.

After sales service and support

Warranty Policy

The entire machine is covered by a one-year warranty.

Lifetime maintenance service is provided, with only parts charged after the warranty period expires.

Emergency response mechanism

The after-sales hotline provides global coverage with multi-channel support including video calls and WeChat customer service.

Repair requests will be responded to within 1 hour, with remote solutions provided within 4 hours; authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local on-site services.

Technical Support

Free operational training (including on-site/off-site modes) and process database updates are provided.

Authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local technical support services.

Spare Part Service

Lifetime provision of original factory accessories (such as high-purity alumina furnace, silicon molybdenum rod, etc.)

Support non-standard customization services to match special sintering process requirements