1h Fast Sintering VS 150 pieces Conventional Sintering

Dual mode drive

Increase production capacity by 50%!

High speed, high quality, and high quantity

make sintering more than just fast

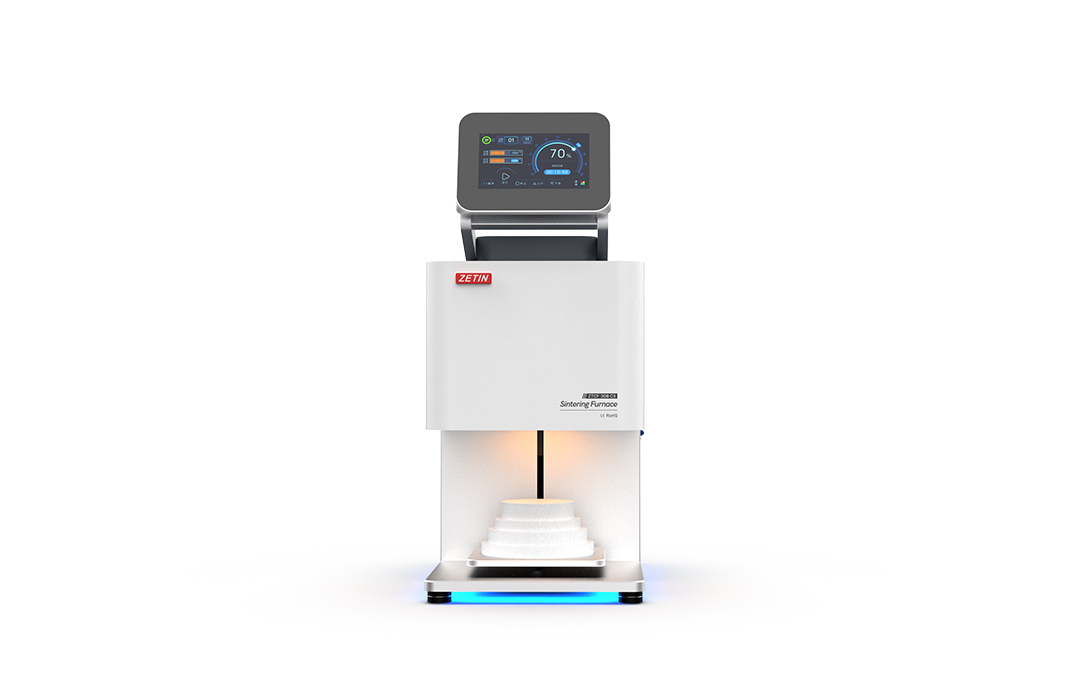

Fast Sintering Furnace

ZTCF-30B Plus

- Breaking through efficiency bottlenecks

- Ensure sintering quality

- Convenient operating system

The fast and slow integrated sintering furnace is a special sintering equipment designed specifically for oral restorations. ZETIN has made a breakthrough transformation and integration of traditional sintering furnaces, achieving full material coverage through dual-mode switching to avoid duplicate equipment procurement. Fast sintering only takes 65 minutes, while conventional sintering can sinter up to 150 units at a time, significantly improving production efficiency. Truly achieving cost reduction and efficiency improvement is an essential and preferred product for technical institutes and laboratories

Breaking through efficiency bottlenecks

- 65 minute rapid sintering

The 65 minute rapid sintering mode has shortened the traditional sintering cycle (2-4 hours) by 60% -73%, achieving the production of zirconia restorations in one chair side diagnosis and treatment, avoiding multiple follow-up visits for patients.

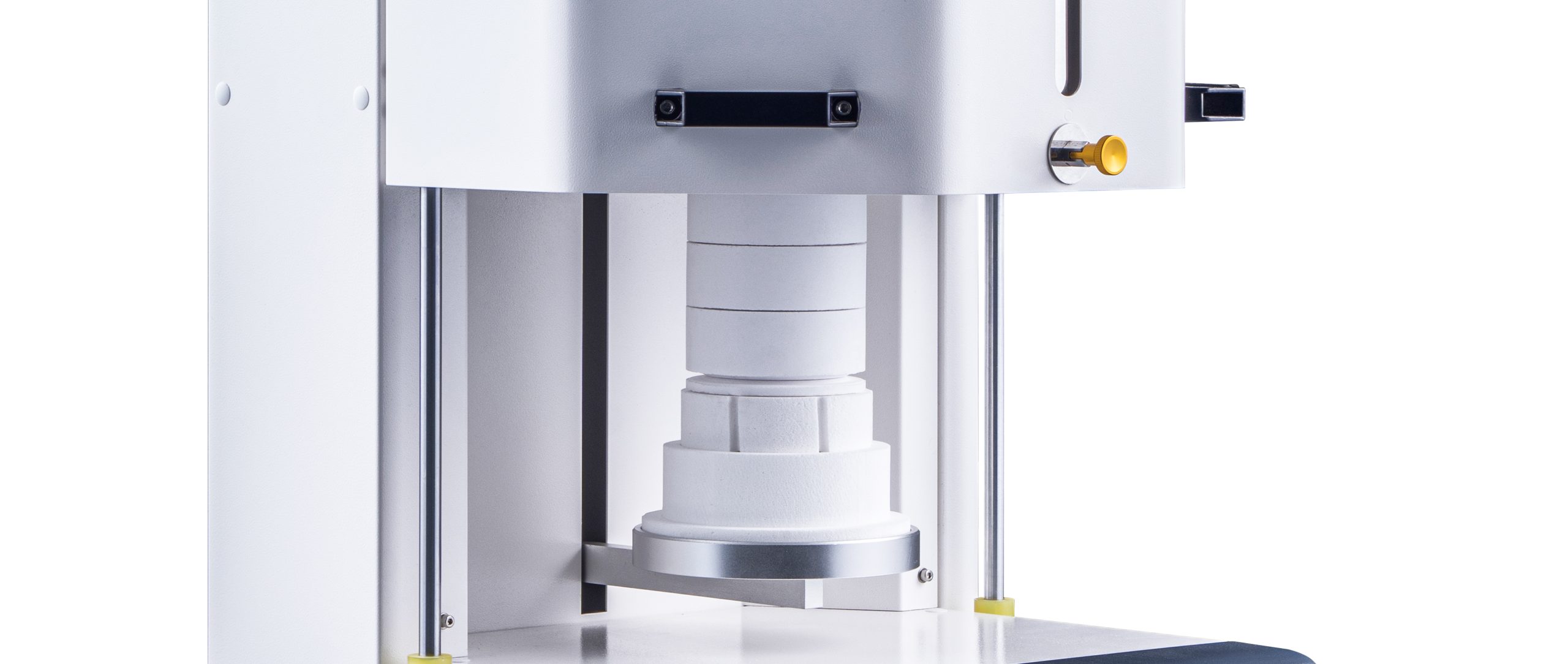

- 150 sintering units

Traditional sintering can simultaneously sinter three layers of crucibles, up to 150 units, truly achieving cost reduction and efficiency improvement.

Ensure sintering quality

- ± 1 ℃ temperature error

PID intelligent temperature control system improves sintering quality and avoids sintering defects

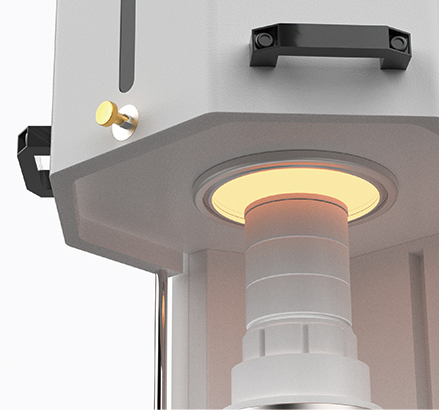

- High purity heating element

Dental grade silicon molybdenum rod with uniform heating process and high sintering quality

- Imported insulation materials

Energy saving and energy-saving, good insulation effect, improved sintering quality, and reduced damage rate

Convenient operating system

- 7-inch high-definition color touch screen

Data visualization interface design, scientifically reasonable button layout, simple and easy operation, reducing job training and improving work efficiency

- 40 preset programs

Record and save customized data with one click operation to avoid duplicate settings or data loss, which may delay work progress

- Power off memory

In response to sudden power outages, the program automatically responds and can continue executing program data after restarting to complete unfinished tasks

Technical parameters

Max.Temperature: 1730℃

Power: 3KW

Voltage: 220V 50/60HZ 110V 50/60HZ

Chamber Size: ∅110mm*120mm

Size: 590*470*850mm(L*W*H)

Net Weight: 85KG

Large Touch Screen

Large touch screen, parameterized design interface, and panoramic display of all parameters.

After sales service and support

Warranty Policy

The entire machine is covered by a one-year warranty.

Lifetime maintenance service is provided, with only parts charged after the warranty period expires.

Emergency response mechanism

The after-sales hotline provides global coverage with multi-channel support including video calls and WeChat customer service.

Repair requests will be responded to within 1 hour, with remote solutions provided within 4 hours; authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local on-site services.

Technical Support

Free operational training (including on-site/off-site modes) and process database updates are provided.

Authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local technical support services.

Spare Part Service

Lifetime provision of original factory accessories (such as high-purity alumina furnace, silicon molybdenum rod, etc.)

Support non-standard customization services to match special sintering process requirements