Elevate Your Retainer Production

Boost Efficiency • Perfect Fit • Unwavering Precision

The automatic pressure former that transforms your lab workflow

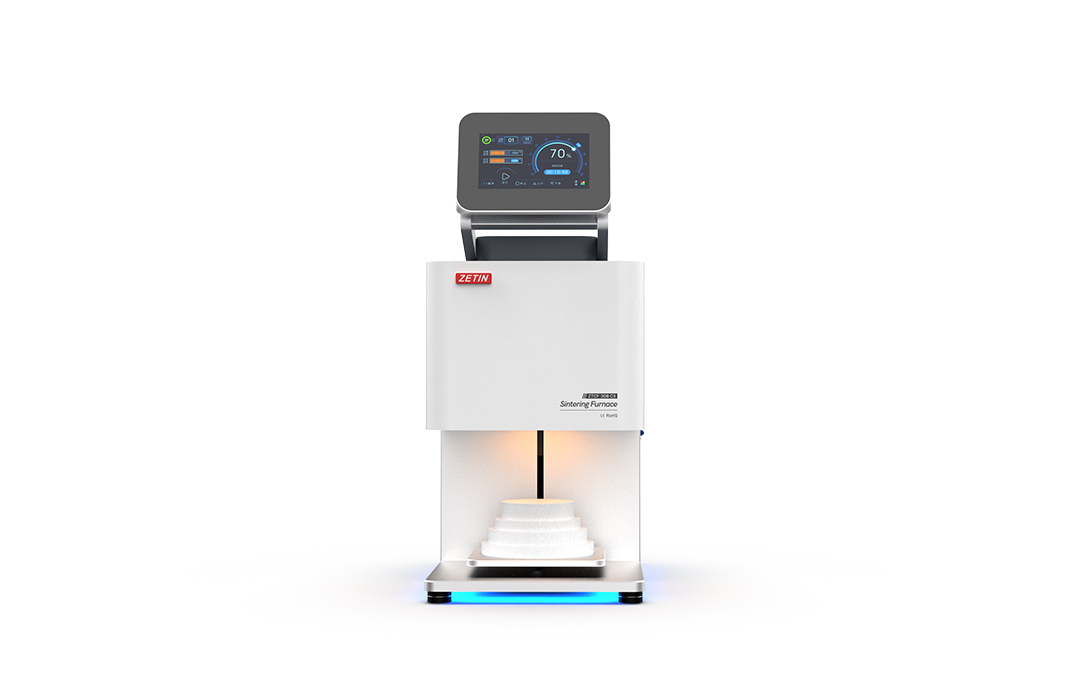

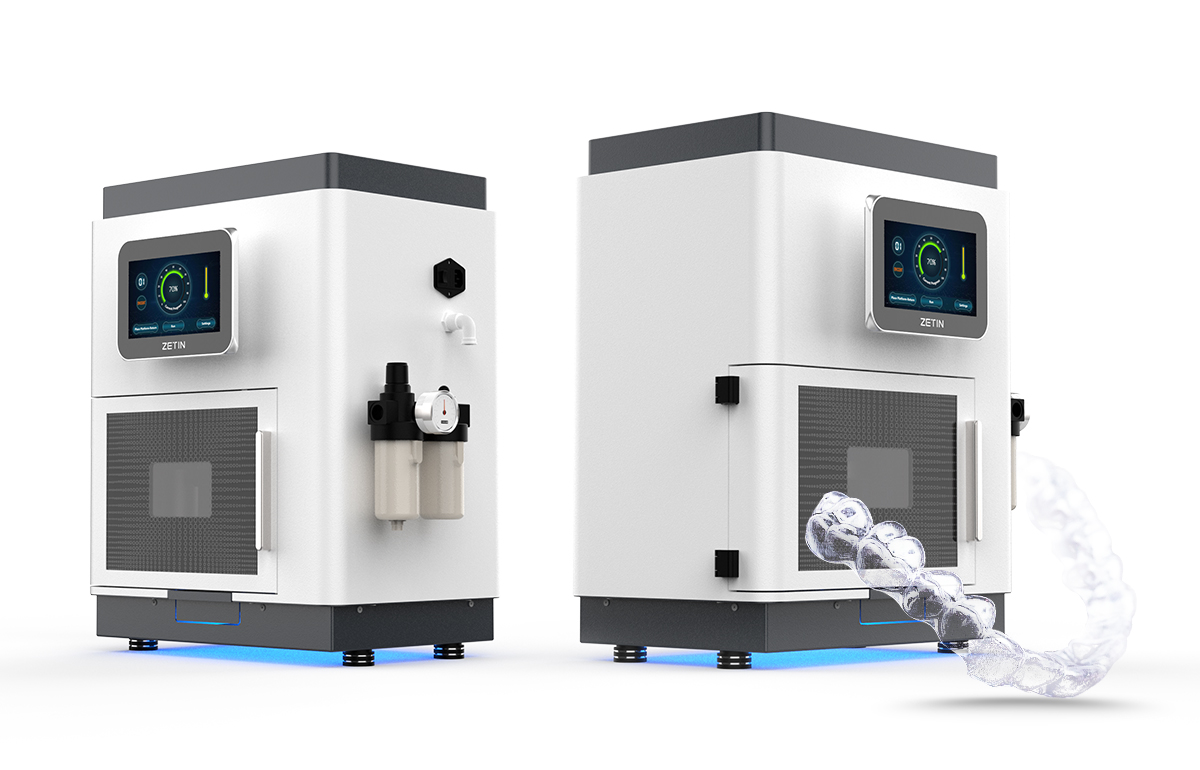

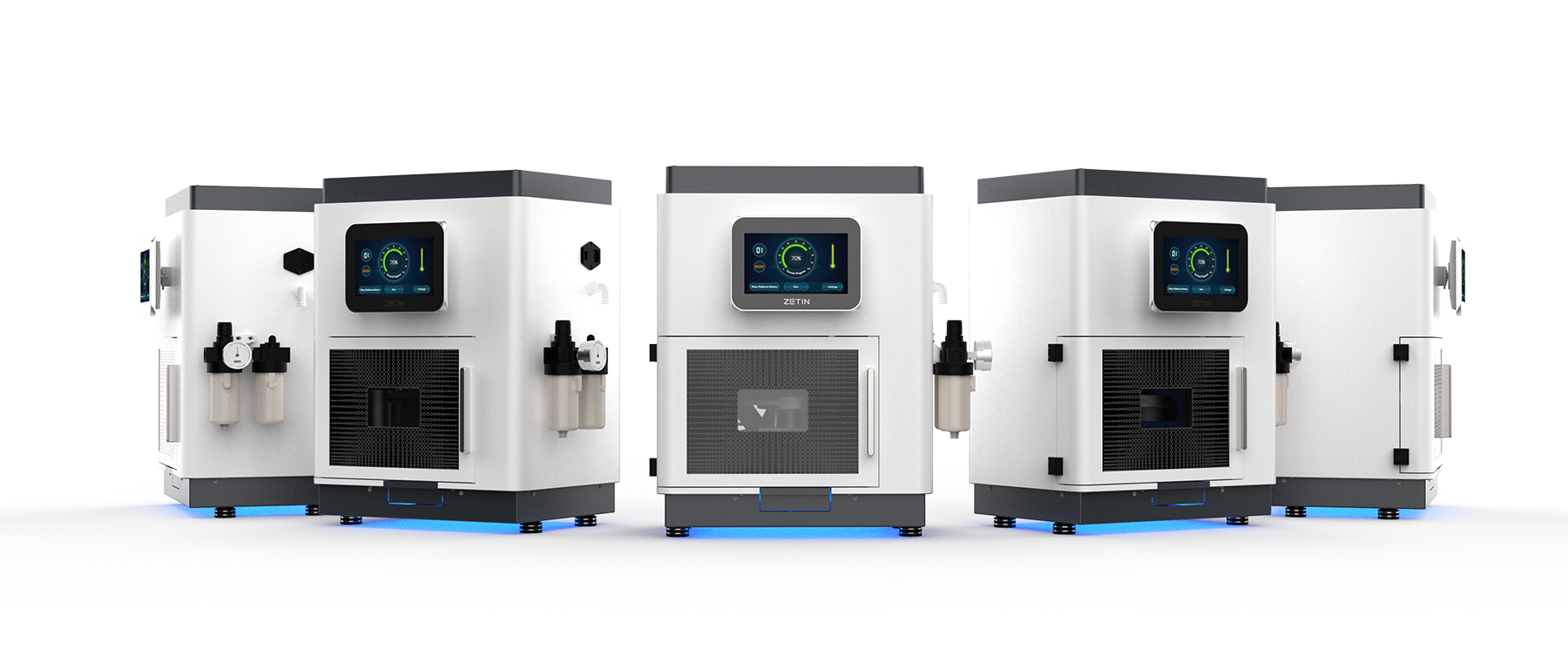

Forming Machine

ZTCF-40A

- Dramatically Boosts Workflow Efficiency

- Delivers a Perfect Fit & Exceptional Patient Comfort

- Ensures Consistent, Reliable Craftsmanship Every Time

This automatic pressure forming machine features a mid-wave infrared precision temperature control system, which heats the film material uniformly from inside to outside, preventing bubbles and local overheating while ensuring energy efficiency and safety. Its vertical pressing technology ensures uniform film thickness and micron-level fitting accuracy, effectively eliminating wrinkles and deformation. Designed with user-friendly and intelligent functions—including anti-misoperation locking, a 7-inch HD touchscreen, fully automated processes, and support for 100 custom programs—it simplifies workflows, reduces training costs, and significantly boosts chairside efficiency in labs and clinics.

Core Technical Performance

- Precision Temperature Control System

Equipped with mid-wave infrared technology, the machine delivers uniform heating and precise temperature control: its moderate penetration depth heats the film evenly from inside to outside, minimizing surface overheating or incomplete internal softening, preventing bubbles, and improving fit accuracy, while the heater temperature can be precisely adjusted via programs to accommodate films of varying thickness, ensuring consistent process stability; additionally, mid-wave infrared transfers heat directly via electromagnetic waves without the need for a medium, boosting thermal efficiency and enabling rapid heating to the target temperature to shorten production cycles, and the uniform surface temperature of the heater eliminates the risk of film deformation or scorching caused by localized overheating, ensuring safe and reliable operation.

- High-Efficiency Forming Capability

The machine uses vertical film heating and pressing technology to ensure uniform thickness of the formed film. Its precision fit control applies directional pressure for even material distribution, achieving micron-level accuracy between the film and dental model to eliminate the localized wrinkles common with traditional horizontal pressing. Additionally, the evenly distributed vertical pressure eliminates stress concentration during film softening, significantly reducing the occurrence of bubbles.

Design & User Experience

- User-Centric Design

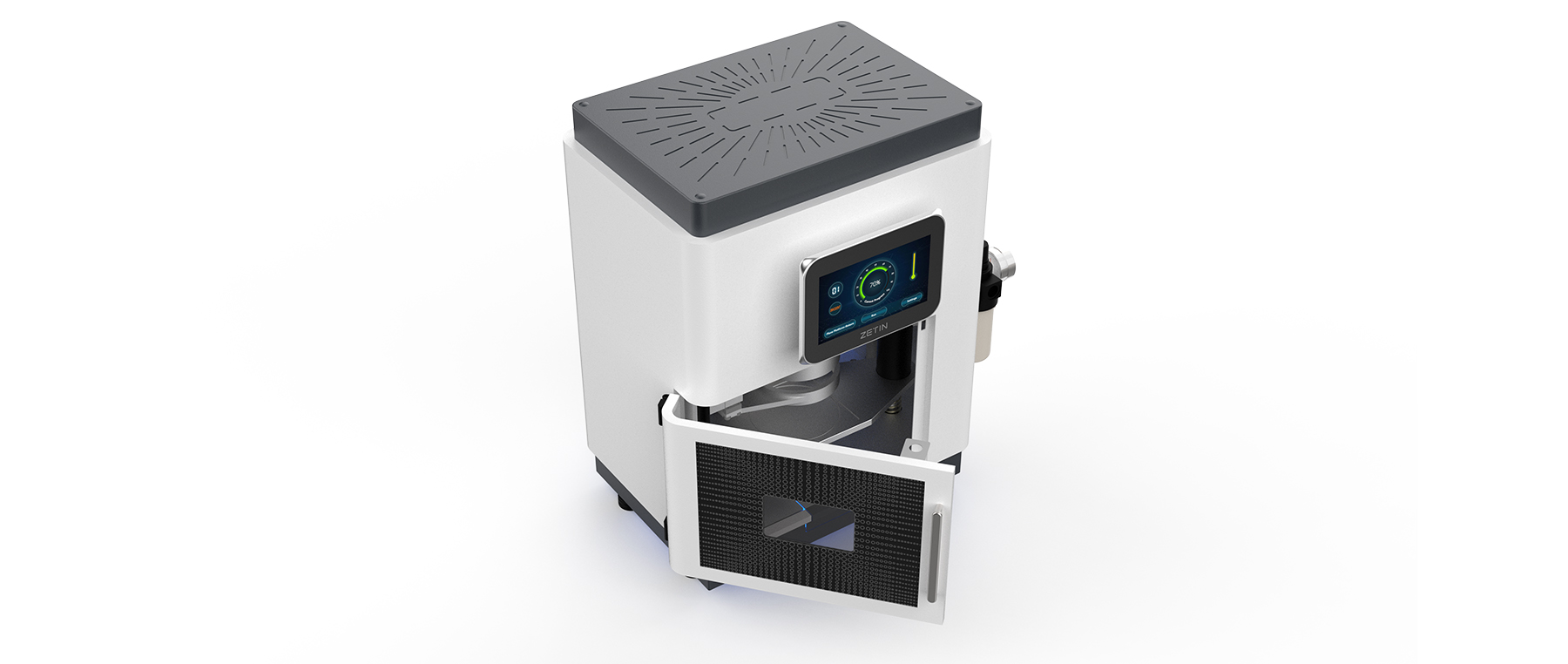

The machine is equipped with an anti-misoperation safety lock that automatically secures the door during operation, ensuring a safe and smooth workflow. It also features a 7-inch high-definition color touchscreen with a data-visualization interface and a scientifically optimized button layout, enabling intuitive operation, reducing training requirements, and boosting work efficiency.

- Intelligent features

The pressing and cooling cycles run automatically to simplify workflows and boost efficiency. The built-in programs support all film types—simply select the film material and thickness, and the machine runs automatically, reducing training costs and improving productivity. It also stores up to 100 custom programs to save parameter settings, enabling personalized service and further streamlining operations.

Technical parameters

Diaphragm diameter: 120mm/125mm

Diaphragm thickness: 0 – 6mm

Pressure: 0.4 – 0.8 Mpa

Noise level: less than 60dB

Power: 910 w

Voltage: 220 – 240V, 50 – 60Hz

Size: 370*420*630 mm(L*W*H)

Net Weight: 52 kg

Large Touch Screen

Large touch screen, parameterized design interface, and panoramic display of all parameters.

After sales service and support

Warranty Policy

The entire machine is covered by a one-year warranty.

Lifetime maintenance service is provided, with only parts charged after the warranty period expires.

Emergency response mechanism

The after-sales hotline provides global coverage with multi-channel support including video calls and WeChat customer service.

Repair requests will be responded to within 1 hour, with remote solutions provided within 4 hours; authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local on-site services.

Technical Support

Free operational training (including on-site/off-site modes) and process database updates are provided.

Authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local technical support services.

Spare Part Service

Lifetime provision of original factory accessories (such as high-purity alumina furnace, silicon molybdenum rod, etc.)

Support non-standard customization services to match special sintering process requirements