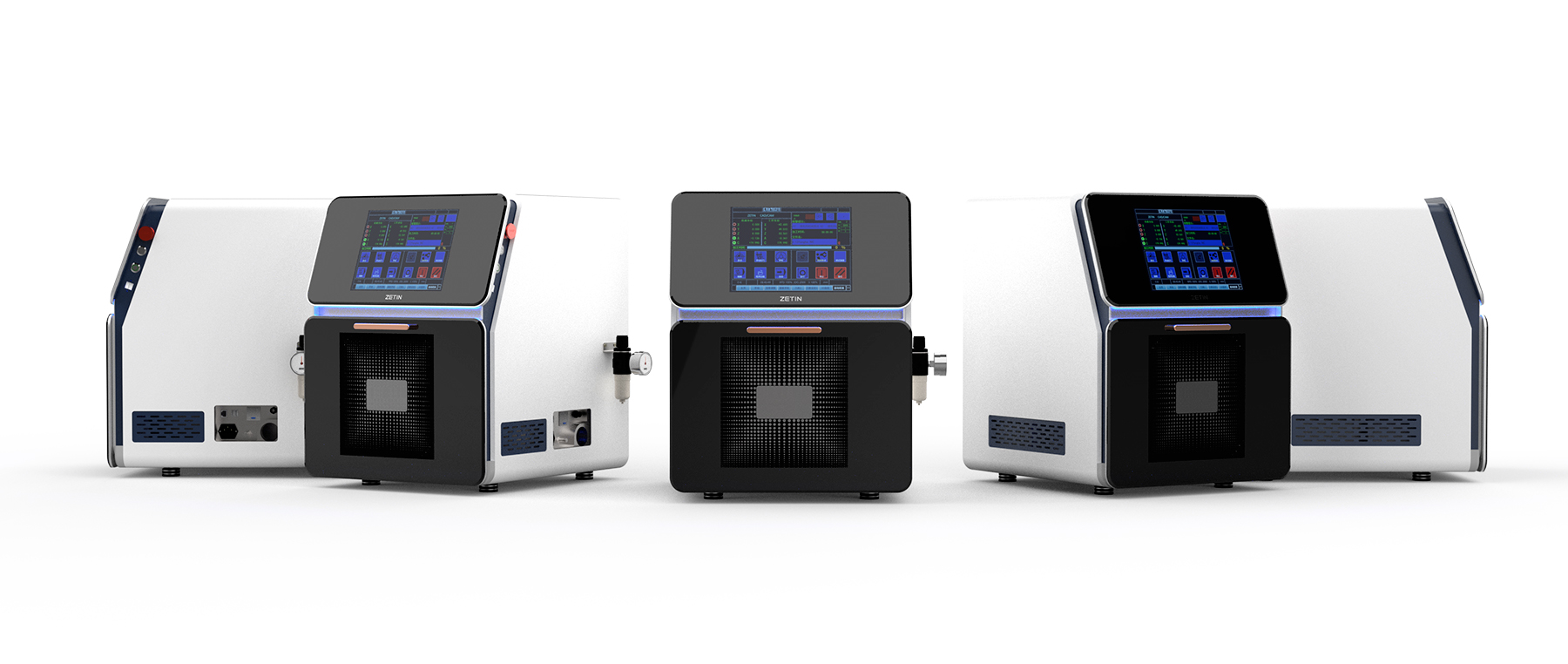

Full-Angle Control, No Machining Blind Spots

5-Axis Linkage Carving for Complex Machining Scenarios

High Efficiency, High Precision, High Compatibility

Milling Machine CAD/CAM

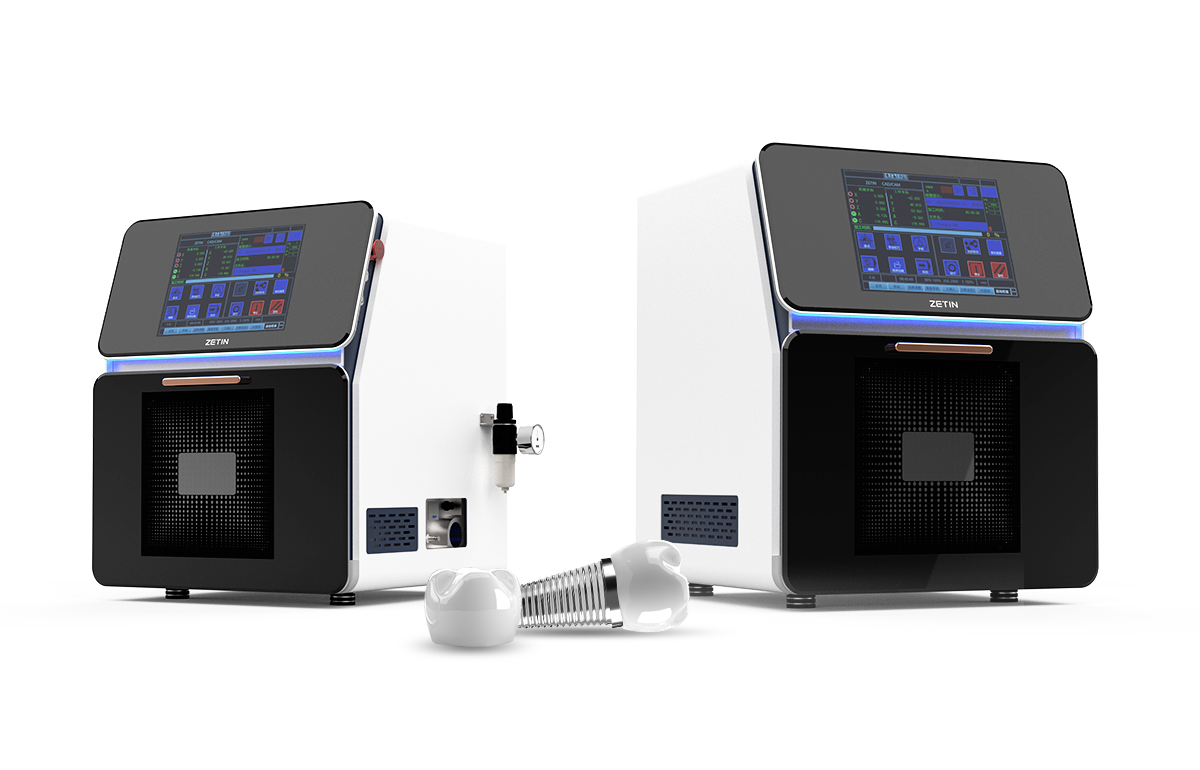

ZTMM-A5

- Handles Complex Carving

- Delivers a Clean Workspace

- Simple, Intuitive Operation

This CAD/CAM-enabled 5-axis dental milling machine delivers industry-leading precision, enabling high-accuracy machining of complex geometries that outperforms traditional 3-axis systems. Its dry-processing technology eliminates coolant waste, cutting costs while boosting efficiency through faster cutting speeds and extended tool life. Compatible with ZIR, PMMA, WAX, PEEK and composite materials, it features a 7-inch touchscreen for intuitive operation and a compact modular design to fit seamlessly into clinic and lab workflows.

Core Technical Performance

- High-Precision Control

Equipped with 5-axis linkage, this machine delivers exceptional carving precision and minimal machining error—far surpassing traditional manual standards to ensure restoration margins meet the highest clinical benchmarks. It also supports high-angle machining to handle complex geometries like deep cavities and undercuts that are inaccessible to conventional 3-axis systems, significantly expanding its application range.

- Dry Processing

This dry-processing system eliminates coolant use entirely, avoiding oil contamination and waste disposal challenges to meet green manufacturing standards, while also cutting overall costs by removing expenses related to coolant procurement, maintenance, and treatment. It delivers faster cutting speeds than traditional processes to reduce per-part machining time, and eliminates thermal shock to significantly extend tool life, especially for silicon nitride ceramics. Additionally, its compatibility with composites, ceramics, and other materials—paired with a vacuum dust extraction system—enables coolant-free machining of complex parts and boosts dust removal efficiency.

- Multi-Material Compatibility

It supports the machining of ZIR, PMMA, WAX, and PEEK materials, with a single unit covering the production needs of a wide range of dental restorations.

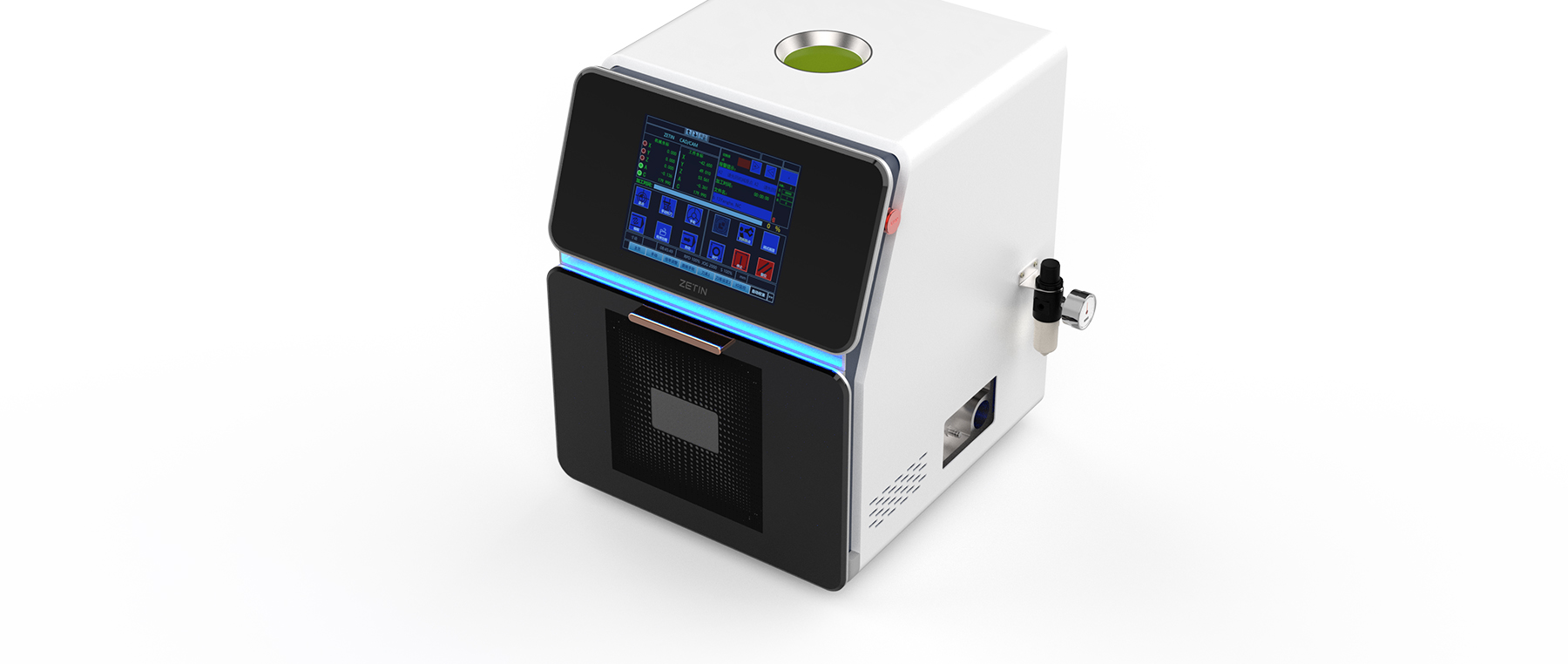

Design & User Experience

- Optimized Human-Machine Interaction

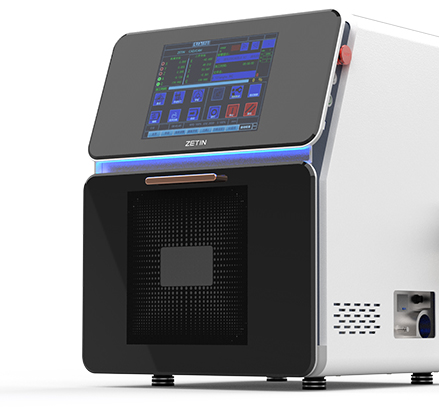

Featuring a 7-inch high-definition color touchscreen, it offers a data-visualization interface with a scientifically optimized button layout for intuitive operation, reducing training requirements and boosting work efficiency.

- Compact & Modular Design

With a compact footprint, it is compatible with external vacuum cleaners and adapts seamlessly to diverse clinical and laboratory settings.

Technical parameters

Axis: Five

Processing Way: Dry cut

Spindle: Max speed 60000r/min

Range of rotation: “Axis A: -114°to +90°”

Tiling rotation: C axis: 360°

Finishing Precision: ±0.005mm

Remote Maintenance: A/S

Tools: 4 knives

Compressed Air: 7bar, 50L/min

Materials to be milled: ZIR, PMMA, WAX, PEEK

The size of material: 98mm*10mm 98mm*25mm

Power: 1.2kw

Voltage: 220V AC 50/60HZ

Size: 525X480X615mm

Net weight: 73kg

Large Touch Screen

Large touch screen, parameterized design interface, and panoramic display of all parameters.

After sales service and support

Warranty Policy

The entire machine is covered by a one-year warranty.

Lifetime maintenance service is provided, with only parts charged after the warranty period expires.

Emergency response mechanism

The after-sales hotline provides global coverage with multi-channel support including video calls and WeChat customer service.

Repair requests will be responded to within 1 hour, with remote solutions provided within 4 hours; authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local on-site services.

Technical Support

Free operational training (including on-site/off-site modes) and process database updates are provided.

Authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local technical support services.

Spare Part Service

Lifetime provision of original factory accessories (such as high-purity alumina furnace, silicon molybdenum rod, etc.)

Support non-standard customization services to match special sintering process requirements