1-to-2 Milling Machine Dedicated

Vacuum Cleaner

Dual-Carving Synchronized Cleaning System

Double cleaning power, one device in control — the perfect combination of efficiency and ultimate cleanliness.

Vacuum Cleaner

ZT-XCQ-2413

- Efficiency and Cost

- Space and Operations

- Image and Quality

A professional-grade dual-outlet vacuum cleaner designed specifically for dental studios with multi-device operations. It can simultaneously connect two engraving machines,perfectly adapting to dental processing scenarios. Each branch is equipped with an independent anti-clogging air duct, maintaining powerful and stable suction even when both devices are running, making it ideal for prolonged high-intensity workloads. Featuring a HEPA-grade filter (capturing particles below 5μm), combined with a primary filter and cyclonic separation technology, it intercepts dust in layers to prevent secondary leakage. The filter is quick to detach, clean, and replace. A low-noise motor (≤70dB) ensures quiet operation without interfering with the precision judgment required for restorations. The all-metal body and wear-resistant tubing are durable and pressure-resistant, compliant with medical electrical safety standards and free from static hazards. The dual-outlet design saves space and cost while delivering synchronized, efficient cleaning to enhance workspace cleanliness—making it the ideal choice for professionals seeking improved efficiency and protection.

Breaking through cleaning efficiency

- Dual-machine connection

One vacuum cleaner can power two carving machines simultaneously, streamlining the application scenario and reducing costs to enhance efficiency.

- Efficient dust removal

The fan delivers a maximum airspeed of 35m/s, with adjustable suction power and the ability to filter particles below 5μm, significantly improving purification and cleaning effectiveness.

- Long-lasting operation

Supports continuous operation for 12 hours, meeting the demands of extended, high-intensity cleaning tasks to ensure consistent performance.

Ensuring cleaning quality

- Automatic cleaning

Reversely cleans the filter to maintain its cleanliness, reduce replacement frequency, and lower maintenance costs.

- Low-noise operation

High-sealing shock absorption design enhances environmental comfort during use.

- Cost and efficiency optimization

Features a brushless motor with an operational lifespan of over 25,000 hours, effectively lowering maintenance expenses.

Optimizing user experience

- Flexible operation

Offers both manual and automatic modes; the auto mode syncs with zirconia carving machines (starts/stops with the machine), minimizing steps and boosting workflow efficiency.

- Compact and portable

Sleek, space-saving design with lockable universal wheels for effortless movement or fixation, adapting to various workspace needs.

- Maintenance convenience

Filters are easy to disassemble, simplifying routine cleaning and upkeep.

Technical parameters

Max Airflow: 6m³/min

Vacuum: 15 kpa

Frequency: 50/60 HZ

Noise Level: <70 dB

Rated Power: 1200 w

WInput Voltage: 220 V

Size: 505x455x675mm(LxWxH)

Weight: 32 KG

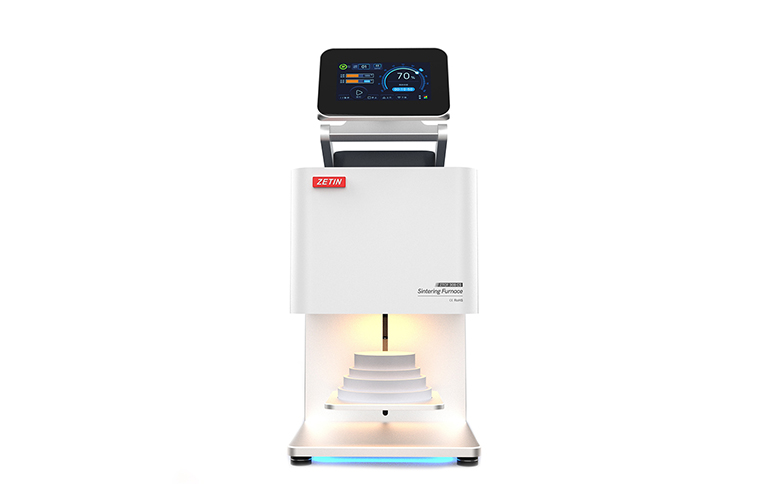

Sleek control panel

Its premium design and intuitive button controls elevate professional cleaning to a new level of efficiency and elegance.

After sales service and support

Warranty Policy

The entire machine is covered by a one-year warranty.

Lifetime maintenance service is provided, with only parts charged after the warranty period expires.

Emergency response mechanism

The after-sales hotline provides global coverage with multi-channel support including video calls and WeChat customer service.

Repair requests will be responded to within 1 hour, with remote solutions provided within 4 hours; authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local on-site services.

Technical Support

Free operational training (including on-site/off-site modes) and process database updates are provided.

Authorized distributors in select countries (e.g., Russia, Dubai, India, Brazil, Vietnam) offer local technical support services.

Spare Part Service

Lifetime provision of original factory accessories (such as high-purity alumina furnace, silicon molybdenum rod, etc.)

Support non-standard customization services to match special sintering process requirements